![]()

![]()

![]()

![]()

![]()

| Questions that need to be answered for your Cableway system |

|||||

Does your system stop and start or does it run continuously? How long does your system run in an average day? Is your system loaded when it starts? |

|||||

| 1.

If line pull does not exceed 750 lbs., one drive will be required.

If it exceeds 750 lbs., two or more will be required. *Should this result in a fraction of a drive, always use the next higher number of drives |

|||||

| 2.

To arrive at total HP required, use this formula Total line pull X Speed in F.P.M ÷ 16,000= Total HP Total H.P. ÷ Number Drives Required= Average H.P. Per Drive |

|||||

| Note: Standard

drives are furnished with 1 H.P. motors. Consult factory on application

requiring motors larger then 1 H.P. |

|||||

|

|

||||

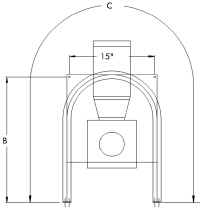

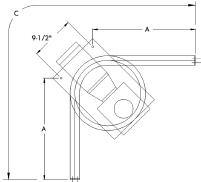

| DRIVE

UNITS |

|||||

| Part # | Sprocket P.D. | Arc of |

A | B | C |

| 9D15212 | 15-1/4” | 90º | 16-1/2” | 36-3/4” |

|

| 9D22912 | 22-15/16” | 90º | 26-15/16” | 55” |

|

| 9D30512 | 30-9/16” | 90º | 32-1/2” | 65-1/2” |

|

| 18D15212 | 15-1/4” | 180º | 20” | 48-3/4” | |

| 18D22912 | 22-15/16” | 180º | 30” | 73” |

|

| 18D30512 | 30-9/16” | 180º | 36” | 89-1/2” |

|

|

|

|||||

|

Cableway Conveyor Menu Anatomy |

|||||